CONTENT ON THIS PAGE IS RETAINED FOR INFORMATION ONLY

DUE TO n-Propyl bromide now being included in Annex 14 of REACH

EnviroTech Europe Ltd (ETE) continue to publish it as historical information and to record changes occurring in legislation which have affected decisions on formulations and equipment used in vapour degreasing - the most effective, quickest, flexible and cheapest cleaning system used in industry.

EnSolv® invented and patented by EnviroTech has been a market leader all over the world for vapour degreasing. It is based on n-bromopropane (nPB) which now cannot be used as a vapour degreaser within the UK or EU without authorisation.

Archived information about EnSolv® can be found using the Discontinued Products & Resources navigation menu on this page.

Using experience accumulated over 40 years supplying and supporting users of the vapour degreasing process ETE specialists have developed “drop in” alternatives:

ProSolv®, ProSolv5408e® and EnSolv CC-A® give the same or improved level of performance and economy as the original EnSolv® products.

Please contact our advisers who are available to discuss your needs and propose the best replacement product.

Or please click here to return to our vapour degreasing products homepage for information about our current products.

As a consultant in surface cleaning technology I have studied the options available and come to the conclusion that the stabilised n-propyl bromide (nPB) sold in the UK under the brand name EnSolv® is the ONLY realistic “drop in” trichloroethylene replacement when used for vapour degreasing. It is on average up to 50% cheaper than fluorocarbon formulations being proposed as alternatives.

From my evaluation it is clear current users of EnSolv® can continue to use the solvent and equipment or if still if using TRIKE you can make the change to EnSolv® in a day. A decision has to be made quickly as the “sunset date” after which TRIKE will not be available for industrial use without auyhorisation in the EU was April 2016 but you can substitute with only minor changes to control settings on equipment. The legislation regarding the use of nPB may change in the future but if this happens you will have at least 3 years to decide on the alternative so the savings in solvent costs over this period will be considerable compared to alternative materials.

Why am I so certain that EnSolv® is the ONLY realistic alternative to TRIKE?

Because it has a boiling point high enough to generate sufficient condensate to ensure proper cleaning, it is not flammable, it has a very high solvency and it is established as completely stable over the last 20 years use in the UK and USA.

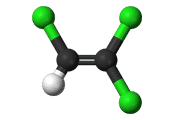

Most of the fluorocarbon solvent formulations are based on trans 1.2 dichloroethene, a close relation to trichloroethylene but which is very, very highly flammable with very low flash point of 2°C. It is a good solvent for oils, greases and other soils and is relatively cheap so complements the fluorocarbon solvents which definitely aren’t. The extremely expensive fluorocarbons solvents represent only a small percentage of the formulations and used only as flame suppressants as they have little solvent power.

To suggest Fluorocarbons can be used in vapour degreasing is being economical with the truth or very naive. Vapour degreasing works using the differential in temperature between parts to be cleaned and the solvent vapour temperature. This differential allows solvent vapour to condense and the liquid removes the oils and soil on the surface of the parts. The differentials at average ambient temperature for Trike is 69°C for EnSolv® 53°C but for fluorocarbons vary between 23/29°C. Condensation will only occur while the surface temperature of parts is less than that of the vapour. Certainly during the warmer months it is clear that the volume of condensed liquid from fluorocarbons will not be sufficient to properly clean parts being less than 50% of that generated from EnSolv®. The KB value, a standard indication of solvent power, is also very much lower which further aggravates the situation.

In preparing this evaluation it is clear that many users are uncertain of the complex and inter related legislation which surrounds the use of these chemicals so I have added a short section on each for clarity.

REACH

REACH is the classification system for chemicals now used in Europe regulated by the ECHA (European Chemicals Agency. EnSolv® is based on n- Propyl bromide (nPB), which was added to the REACH Candidate List of Substances of Very High Concern (SHVC) in December 2012. This description SVHC is often misunderstood and will be misinterpreted by many suppliers of alternative solvents based on fluorocarbon formulations and other exotic mixtures, implying the use of EnSolv® (nPB) is subject to immediate restrictions on its usage, when offering these products. This is not the case, as you will see from the detailed explanation below, you can be assured that you can continue to use nPB now, and subject to authorisation, into the foreseeable future.

The next step for SVHC chemicals is to be added to the Authorisation List (Annex XIV) of REACH which means they will be subject to an authorisation process for specific applications. In the coming months or years, the EU Member States will vote on a recommendation by ECHA for nPB to be added to this Authorisation List (Annex XIV). If this happens then there is still 18 months to submit authorisation requests and, in the unlikely event that these are refused, another 18 months at least before the Sunset Date after which usage for non-authorised applications will be banned. So the latest date for authorisation requests will be sometime after the 31st January 2017 and if refused, a Sunset Date not before the 31st July 2018. So for at least 3 to 4 years using EnSolv® will be a sensible and safe way to save a great deal of money compared to the unnecessary use of very expensive fluorocarbon mixtures.

I understand the manufacturers of EnSolv® are already working hard with their team of experts to put together the necessary documentation, arguments and evidence to enable authorisation for nPB to be used for vapour degreasing. The authorisation process is still under development by ECHA and changes are quite likely in the near future so it is difficult to explain what exactly you will need to do to obtain permission for your individual process. This will become clearer in the next few months. Users can be confident however that when using EnSolv® in appropriate equipment, authorisation will, most likely, be given.

Let me be clear, if you decide not to get involved in an authorisation application for EnSolv®, but choose to change to an alternative fluorocarbon such as ProSolv® (also developed by EnviroTech), you have over 3 years to make that change.

Chemicals are an essential part of every aspect of modern life and are under constant review to ensure safe usage. The manufacturers have been pro-active to ensure all the substances used in the formulation of EnSolv® have been pre-registered for REACH and I am assured, will always ensure that this product complies with existing and future legislation.

Preparing this article I have used the vast database of information about nPB and EnSolv®, its effects on people, the environment and materials of manufacture.

If you have problems or projects related to metal cleaning or pretreatment contact me on streacher@envirotech-europe.com for information or advice.

We can provide you with a Material Safety Data Sheet, independent laboratory reports, product samples or technical assistance. For more information or advice please contact us by telephone on +44 (0) 20 8281 6370 or use our contact form.

Vapour degreasing solvents are supplied and supported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.